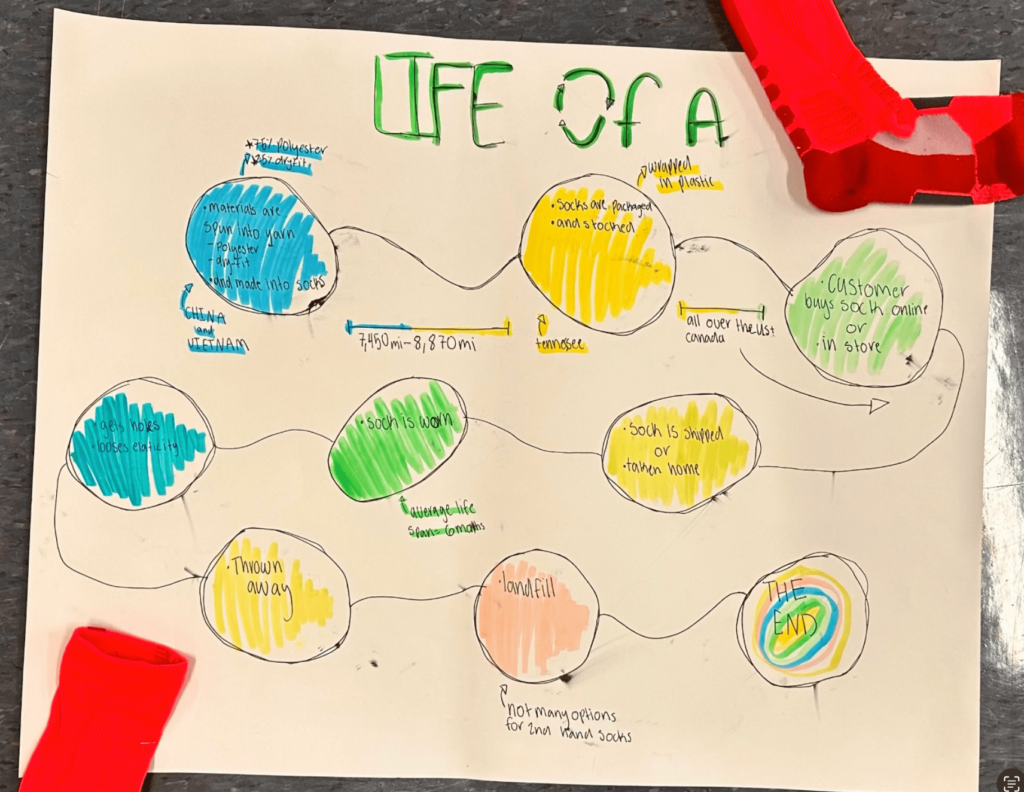

From Sole to Soul: The Extraordinary Journey of a Sock. Yarn to landfill the nike elote sock goes through many phases.Though the sources of the materials used in these socks seemingly is kept under lock and key the movement of these socks before they reach the consumer can be found, Starting in a factory in Vietnam the dry fit and polyester are processed and spun into yarn. This yarn is shipped to China where the sock panels are sewn together to make the sock form. Then they take a 8,000-mile trip to Houston Texas where they are stocked and packages to be ordered online or shipped to stores. Though we wear socks every day we don’t often think of the process of taking that thin piece of fabric that separates our feet from our shoes from Vietnam, to China, to Houston, and finally to your sock drawer. If we truly want to become sustainable it is important for us to examine the production of objects we use in our everyday life.

A sock, in the eyes of most people, seems quite harmless, yet it is far from it. The Nike Elite sock is 75% polyester and 25% dry fit. Polyester is derived from petrochemicals, which are non-renewable fossil fuel resources, and the production of polyester requires large amounts of energy and water. Along with polyester’s direct greenhouse gas emitition, it is also particularly not bio-degradable leaving behind microplastics that further contribute to the pollution of our environment and air. The large amount of transportation used to just simply in the production of the sock is largely by plane and as we know jet fuel is a main contributor to our current climate crisis.