By Owen Brent-Levenstein and Cana Yao

Everything you interact with on a daily basis has a carbon footprint. While you might think of a carbon footprint as a direct product of environmental costs. For example, even just buying a bag of chips can lead to a lot of questions: how were the ingredients sourced? How was the plastic bag made? How and where were the chips cooked and packaged? What did the transportation process look like? Where will the bag end up after the chips are eaten?

Everything you interact with on a daily basis has a carbon footprint. While you might think of a carbon footprint as a direct product of environmental costs. For example, even just buying a bag of chips can lead to a lot of questions: how were the ingredients sourced? How was the plastic bag made? How and where were the chips cooked and packaged? What did the transportation process look like? Where will the bag end up after the chips are eaten?

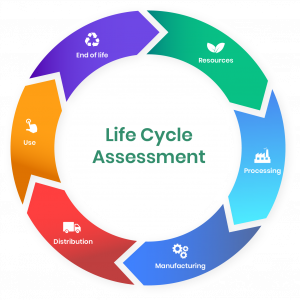

A few weeks ago, our Environmental Sustainability class attempted to answer some of these questions by conducting life cycle analyses on everyday items they bought in the student store, from a bag of cheetos to a sweatshirt. A life cycle analysis is a method of assessing the environmental impact of a product from cradle to grave, looking into not just the impact of disposing of an item, but also the impact of the creation and transportation of all of the materials needed to make it. Throughout this process, we developed new research skills as well as a greater understanding of the hidden emissions in everyday products.

Image by Cana Yao

One of our key takeaways from this project was just how much buying a container (such as a plastic bag) alongside a product (such as Cheetos) can contribute to its carbon emissions. For instance, in studying Cup Noodles, we found that the noodles’ cooking and drying process was not the only part of its life cycle contributing to a high carbon footprint–rather, a key factor was the four layers of packaging: cardboard, styrofoam, plastic, and paper, as shown in the image on the right. We had similar findings with Gatorade, Fairlife Core Power Elite, Cheetos, Naked Smoothies, and Bull and Bean: packaging really makes a difference.

Through our research, we also found that due to transportation emissions, buying products locally makes an enormous difference. For example, buying chocolate milk from Fairlife involves sourcing milk from one of Fairlife’s 99 farms around the U.S. and shipping it to one of two plants either in Michigan or New Mexico for processing. New ingredients are added, it gets bottled in PET plastic and driven by semi truck to a distributor who transports it to DA. Discarded bottles are trucked to landfills or recycling plants.

There are many possible solutions to the two issues we identified. For example, buying more from local companies like Bull and Bean would make a big difference in shipping emissions, decreasing both the distance traveled to source the ingredients as well as the miles traveled to deliver the final product to school. Additionally, asking companies to change to more sustainable packaging and being mindful of what packages can be recycled or terra-cycled can significantly reduce the negative impact that packaging creates.