The Life Cycle of a Durham Academy Baseball Uniform

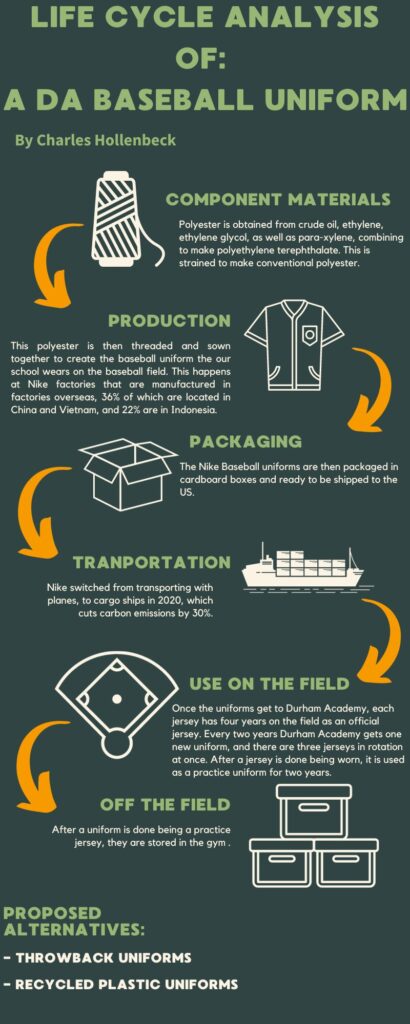

Every DA baseball player has three uniforms. How do they get here? Where do they go after their time on the field? The components of the uniforms can be found by going the website where they’re ordered: the BSN Vault. The specs for a Nike baseball uniform reveal that our uniforms are 100% polyester, a material that is created from crude oil, ethylene, ethylene glycol, as well as para-xylene, combining to make polyethylene terephthalate. This is strained to make conventional polyester. Next in the production process, the creation of the actual uniforms.

The polyester is then sown into a Durham Academy uniform at a Nike manufacturing factory overseas, 36% of which are located in China and Vietnam, and 22% are in Indonesia. Then the uniforms are packaged in a cardboard box that Nike claims to be made out of “recycled materials” and uses a new box design that reduces cardboard usage by 16%. The package is then shipped on a cargo ship that reduces carbon emissions by 30% after previously using cargo planes. This switch was made in 2014. Next the package arrives and is ready for use at Durham Academy on the baseball field. Each uniform has four years on the field as an official jersey, with Durham Academy getting two new uniforms every two years, and there are three jerseys in rotation at once. After a jersey is done being worn, it is used as a practice uniform for two years. After a uniform is done being used as a practice uniform, it is disposed of by being put into a box in the gym. For the past 20 or so years, Durham Academy has been keeping their uniforms in the gym, so every uniform is in there.

The first alternative to buying new uniforms is using old uniforms after they’ve been shelved for ten years, thus bringing throwback uniforms to Durham Academy baseball. This would decrease the amount of money spent on uniforms and materials wasted from old uniforms. This action would recycle the old uniforms over and over so that we are not buying new ones when we want, but instead when we need them. There also has to be a surplus or uniforms from over the years that are in the gym. Another alternative is using baseball jerseys that are made from 100% recycled plastic. The company “Impact Eco Wear” creates these uniforms using the plastic from 12-14 plastic water bottles.

References

King, A. (2018, December 13). Branding, Packaging, and Labeling of Nike [Online forum post]. Prezi. https://prezi.com/p/pcxphcs5apbt/branding-packaging-and-labeling-of-nike/

Morey, K. (2014, April 16). Economic impacts of transporting Nike. Just Trade. https://justtradeplnu.wordpress.com/tag/nike/#:~:text=and%20other%20products.-,Nike%20made%20the%20decision%20to%20transport%20their%20products%20on%20cargo,decreased%20by%2030%25%20in%202020

Nike baseball vault. (n.d.). Retrieved November 13, 2023, from https://catalogs.bsnsports.com/Nike-Baseball/13/

Who manufactures Nikes? (n.d.). Fashinza. https://fashinza.com/brands-and-retail/news/who-manufactures-nikes/

Why is Polyester bad for the environment? (2021, February 23). Kleiderly. Retrieved November 13, 2023, from https://www.kleiderly.com/our-blog/why-is-polyester-bad-for-the-environment#:~:text=Since%20polyester%20is%20made%20of,water%20of%20the%20local%20population

Recent Comments